Part 2: Space Transport Methods

In Part 1 we discussed the basics of the relevant sciences, including propulsive forces (Section 1.3) and energy sources (Section 1.4). These two items can be combined into one or more space transport methods. In Part 2 we will discuss the numerous transport methods, including those in current use, in various stages of development, and proposed or theoretical ones. Before looking at individual methods, we will briefly look at why reaching space has been so difficult and expensive in the past, and what can be done in general to change that situation. We also present some reference tables listing the various methods.

The Space Transport Challenge

editAn ideal transport system has an infinite life and minimal operating cost when delivering a desired cargo. Real systems never reach that goal, and the designer's job is to approach it as closely as possible given the level of technology and other project constraints like funding and schedule. For air and space transport, the desired cargo is called a Payload. For transport purposes it is measured in absolute mass (kg) or Mass Fraction, which is the percentage of payload mass to total vehicle mass including payload.

The Historical Problem

editThe difficult job of the mid-to-late 20th century rocket designer was to find the best compromise between high cost and small payload when going to Earth orbit. This compromise was forced by three factors which conspired to produce a small payload fraction, and therefore high relative cost:

- The mass and size of the Earth, which determines the velocity needed to reach orbit,

- The energy contained in chemical rocket propellants, which determines how much of them you need, and

- The strength and other properties of the materials used to build the rocket, which determines the mass of the vehicle hardware.

It happens that the combination of these three factors produced a small, or even negative payload in an ideal one piece, long life rocket. The total launch mass of such a rocket consists of 3 main parts: Propellant, Vehicle, and Payload. Payload mass is what is available after accounting for the first two, and in 20th century designs that remainder could be negative, or at best a few percent. For example, a single stage LO2/LH2 vehicle with a mission velocity of 9000 m/s and an exhaust velocity of 4500 m/s might be 86.5% fuel, 10-15% vehicle hardware depending on operating life, and therefore -1.5 to +3.5% payload. The lower hardware weight was associated with more flimsy single use construction, and the higher weight with thicker long life design. LO2/LH2 was the highest energy fuel combination. The large ratio of rocket to payload weight led to high launch cost measured in $/kg.

Various compromises had to be made from the ideal concept of a vehicle you could just refuel and launch again like an airplane. One was to make the hardware last just a single flight, thus allowing lighter structures than ones built to last many flights. Another is to drop parts of the vehicle during flight, producing a Multistage Rocket. As fuel is used up less thrust is required to maintain acceleration, so fewer or smaller engines are needed. Tanks also get emptied, so you can drop the excess engines and tanks once you don't need them any more. The remainder of the vehicle starts anew to accelerate towards orbit, but has the benefit of the velocity gained with the previous stage, and less vehicle weight. Low service life and staging are are expensive - you have to replace or re-assemble the hardware, but were necessary given the state of technology. The designer had to find the best balance between high cost due to small payload, or high cost due to discarding or rebuilding a complete rocket. Single-use, multi-stage rockets are still the most common method used to reach Earth orbit, and so space transport to date has been very expensive.

21st Century Solutions

editThe mass and size of the Earth and the energy in chemical propellants are fixed, and structural materials improve fairly slowly. Significant improvements in cost can come from using the latest materials, optimized fuel choices, and recovery and reuse of vehicle parts. But ultimately chemical rocket designs are limited by orbit velocity and fuel energy, which are fixed values. To make more dramatic changes in cost we therefore must break one or more of the 20th century's limiting factors. For example:

- You can build large structures that span part of the Earth's gravity well. This reduces the velocity the vehicle needs to provide. Even a small reduction shifts the near-zero payload fraction into positive territory. Past systems have implicitly assumed chemical rockets do the whole job of reaching orbit, because it was the only type of propulsion considered useful for that job. There is no physical law that demands using one type of propulsion for the entire job, and using multiple methods often gets better total performance.

- There are now a multitude of alternatives to traditional chemical rockets, ranging from some in actual use, to those merely theoretical as yet. Part 2 of this book attempts to list all the known ones, of which there are 83 so far, not including variations. Many of them have better performance, reducing the fuel required and increasing the net payload.

- Since the mid-20th Century, better structural materials and lighter weight components have emerged, but some current rockets still don't take advantage of them.

Although having more options is more complex, the modern designer should consider the full range of available transport methods, and apply them where they function best. The potential gain in going from short life, low payload transport to long life, high payload designs more than justifies the extra work.

Beyond Low Earth Orbit

editFrom an orbital mechanics standpoint, Low Earth Orbit, (LEO) is the altitude range below 2000 km, or about 1/3 of the Earth's radius. In this region the Earth's gravity is more than 58% of the surface value, and orbit periods are less than 50% higher than the 84 minutes of a theoretical orbit at sea level. From a practical standpoint, LEO is the altitude range of 200 to 1,000 km. This is above significant atmospheric drag, and below the Van Allen Radiation Belts. The historical space transport problem was to get from the ground into this orbit range. Travel beyond LEO has not been as constrained to chemical rockets as initial launch. That is because for vertical rocket launch you need to be able to accelerate the whole vehicle at more than one gravity (9.8 m/s2) in order to take off at all, and maintain a relatively high thrust to prevent hitting the ground again while still below orbital speed. One of the key features of chemical rockets is their very high thrust to mass ratio. This made them attractive despite their low absolute efficiency.

Once in a stable orbit, lower thrust levels can be used to travel further, since you are not in danger of immediate re-entry. So alternatives to chemical rockets have been examined for those missions, and some of them even put to use in recent decades. There are now more alternatives for going beyond LEO, which give better performance or wider design choices. The larger change, however, is in the first step of getting to LEO, which was limited to one relatively low performance method until recently.

Known Transport Methods

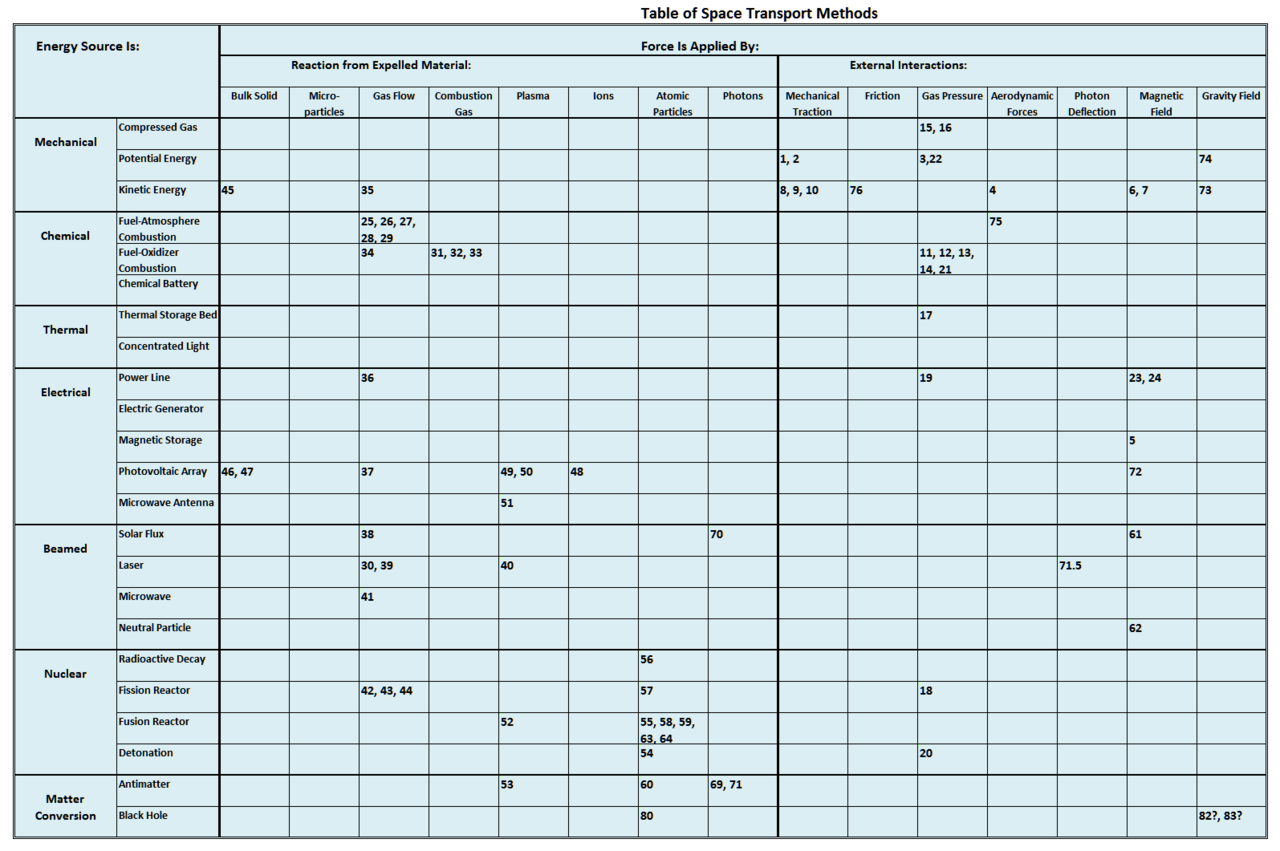

editAs a starting point for designers, Figure 2.0-1 lists the 83 main space transport methods known to the book's authors. They are described in more detail in the following sections and are organized into logical categories by type. The order listed here and later in the book is by similarity of type, and not by feasibility or development status. Those factors are considered later. Many of these methods also have variations in the concept or application. From this list, the designer can then narrow the choices to the relevant options for a particular project, and eventually the final selection. By starting with all of them, you can be sure no viable option is missed.

Figure 2.0-2 places the same transport methods in a table by their numbers, since including the names makes the table too large. Rows in the table indicate different energy sources, which are grouped by major types. Columns indicate how force is applied to generate motion. They are grouped in two main categories: (1) expelling a material, which generates an opposite reaction force by Newton's Law, and (2) the vehicle interacting with outside materials or forces. The table is an aid to organizing and thinking about the methods. Some theoretical methods are not shown on this table, since we do not have definite designs for implementing them. Some of the methods could span more than one box if all their possible variations are considered, but we have assigned them to single boxes in this version. Empty boxes can stimulate thought about possible transport methods which are still unknown, or whether that particular combination truly lacks possible use.

These two figures represent the state of knowledge in mid-2012. There are likely some additional methods not yet known to the authors, and new ones will likely be devised in the future. If a serious project is contemplated, designers should survey the relevant specialists and literature to include the latest concepts.