Brewing/Milling

| Brewing Wikibook |

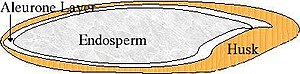

The milling of the malted barley is a very important step. Milling is done to better allow the mashing liquor to access the centre of the barley. This allows the enzymes secreted by the aleurone layer to act upon the starchy endosperm (see Figure).It is important that the grain husk remain intact, as the husks are used to form a filter bed during lautering, the process where the sweet wort (pronounced wert) is run off from the mashed grains.

At the end of milling, the brewer should be left with a range of fragments of barley, and largely intact husks, but no whole grains. There should be little flour, as this leads to haze in the final beer and is poorly retained by the husk bed in the lautering process. It is also important that most of the endosperm is broken up, as this aids enzymatic action due to exposure of a greater surface area of endosperm, and leads to better conversion of the starch to sugars.

Large diameter (8") smooth rollers running at different speeds are preferred. Smaller grain mills can be made with slotted or knurled rollers but the mill gap must be set wider to avoid crushing the husks. Typical hobby grain mills have rollers with a diameter of 1.5 inches. These rollers are knurled so the small rollers will pull the grain through. Because of the smaller area of contact between the rollers and the grain the gap between the rollers must be closer than larger rollers. Also the knurling on the rollers will shread the husks more than larger rollers.

It is also quite possible to mill barley in a kitchen mortar and pestle - although this is exceptionally tedious. A typical kitchen mortar and pestle can handle about 150g of grain at a time, and a typical 5% alcohol beer might take 6kg of malt to make 19 litres. However, the mortar and pestle approach allows a home brewer to experiment with grain mashing, without the expense of a mill.