Chapter 5.5 - Starter and Expansion Sets

The goal of the personal production example is supplying a range of basic products for a community of owner-operators. They do this as individuals or through joint effort for larger tasks. Example products include furniture, home improvements, food, and utilities. The community starts with smaller and simpler projects and works up to larger and more complex ones. We assume they start with limited funds, time, equipment, and skills. So part of the effort is improving themselves as people to overcome these limits.

Community projects may start with as little as one person's part-time effort and no equipment or skills. So we describe some basic tool sets for general household and home improvement/do-it-yourself projects (Section 3.0), with suggestions on use and gaining skills. Community members can then start projects based on the people and resources at hand, and work towards adding equipment and gaining skills. We then discuss workshops, and present a variety of expansion sets for more specialized and advanced projects (Sections 4-8). Items from these sets can be added to the basic ones according to interests and need.

A small collection of tools, and the skills to use them, have a limited capacity to self-improve. But they can be used to make basic items or provide services. Sales or labor can then be used to add to the collection. As the collection grows, the ability to self-improve grows even faster. This is from working with more materials and being able to do more combinations of steps. A large enough collection can be used to improve itself, and make most of the basic products people need and want. But reaching that point requires a community. No one person has all the skills needed, some tasks need multiple people, and few individuals have all the other resources required.

1.0 - Necessary Inputs edit

Accumulating a set of tools and learning how to use them is itself a project. Expanding it so it can make improvements for itself, and a range of desired products, is a series of additional projects and tasks. A working system pf people and equipment to do this requires various inputs and emits outputs in the course of a given project. These include:

- Time - from one or more people to make plans, look for and acquire needed items, operate equipment, train others, or learn skills as needed.

- Supply sources - for parts, materials, tools, machines, training materials, plans, and instructions.

- Money - for items which can't be made internally, or for outside labor that project members can't supply.

- Sheltered Space - to store and use the equipment. Even outdoor equipment should be protected when not in use.

- Energy - such as electric power or human muscles, to make, set up, and operate the equipment.

- Maintenance Items - like water, cleaning supplies, and waste disposal during and after operations.

We suggest starting by assessing which of these you have and which are lacking. The next step is to make a plan for getting enough of the inputs to get started, and how you will continue from there. For example, if you don't have all the basic tools from List 1 (below), you can make a shopping list of the missing items, then either buy them, start saving to buy them, or find a Makerspace/Hackerspace (community workspace), community group, or neighbor that allows you to use them. If you have no idea what is needed for a particular project or how to do the various tasks, entering "how to" followed by the subject into Google Search or some other search engine will generally get you useful results.

In modern society, money can commonly be traded for most other things people need and want. If lack of money is an obstacle, there are ways to overcome that. One is to cut expenses, such as eating out less or sharing living space. Another is to increase income, such as doing basic jobs for other people in addition to current work, or upgrading your knowledge and skills so you can find better work. Finally you can split the cost of needed items across a group.

Reaching a goal may seem like a big challenge. Breaking it down into smaller steps, putting them in order, then taking them one at a time is more manageable. But you have to take the first step to get anywhere.

2.0 - Starter Set Lists edit

Some species besides ours use tools. We are unique in the variety and complexity of our tools, and that we use tools to make other tools. So which of the many options should be included in a starter set? The answer for particular project types, and improvement paths beyond the starting point, will vary widely.

The lists below are a general guide for consideration and selection. You don't need every item from any of the lists to start making things. But the more of them you have, the more kinds of projects you can do. The lists also don't cover every possible project. They are intended as starter sets to build on, not complete lists of every possible tool. Additional items may be needed for particular projects. For large and complex projects you may need multiples of each item, either different sizes and types, or for multiple people to use. For example, a saying in woodworking is "you can never have too many clamps", and generally several are needed at a time. Item names are highlighted in bold, and many are linked to Wikipedia articles. Wikipedia is a sister project to Wikibooks, where this book is maintained. We also link to other sources for more detail.

Sources - The lists below are compiled from a number existing tool and equipment lists, and other reference sources. The intent was to gather and sort by project type the the items most needed to get started. The source lists are from several makerspaces, a tool bank (which lends out tools to nonprofit groups), a book on rural workshops, the phased equipment list for the Seed Factory Project, a pamphlet from manufacturer Porter Tools, a course on "manual arts" (later called "shop class" in schools), a compiled list of equipment for industrial training classes, a website for beginning machinists, the author's personal tool list, a contributed list to these books, recommended tool brands from an online forum, a woodworking list from a YouTube channel, and a study of small industry in India. In addition, many targeted web searches were done for specific categories.

List Types - There are basic tools that have proved useful in many circumstances, from general home use to industrial production. Others are more specialized for specific tasks. For example, an axe is useful in dealing with trees, but useless for cutting steel reinforcement for concrete. So lists 1 and 2 below are basic sets for common home tasks and simple home improvement/do it yourself projects. This is followed by expansion sets for more advanced and specialized projects.

The lists are additive, meaning you should start with items from the basic sets, then add to them from the later lists as needed. Figure 5.5-1 shows a suggested path from the two basic sets to the more specialized ones. The later lists are grouped into small indoor, large indoor, outdoor, and construction based on the location and space needed. Construction produces more indoor space, enabling a cycle of growth and improvement. Depending on the needs and interests of the community, they can choose items from any or all of these lists, and go beyond them.

List Sections - Tools and machines can be classified according to size, power level, and cost. The general groups are (1) manual hand tools, (2) portable power tools, (3) stationary equipment, either powered or not, and (4) mobile equipment that is towed or can move itself. Cost and space needed tend to increase with each group. The lists are generally in order from the smaller, less expensive, and most needed first, but some items are needed together to complete a task. For example drill bits go with an electric drill. We try to note when that is the case.

To go beyond these lists, you will need to know what projects and products you want to make, and the methods and equipment needed for them. Many instructional books and articles have explicit lists of the equipment needed. Others implicitly identify useful tools by discussing their use. Tool and supply catalogs, and the tool sections of online marketplaces can also be reviewed to identify candidate items.

Choosing Equipment - A given tool type, like a claw hammer, can be found in many versions with different quality, weight, intended usage, and cost. So the first thing is to understand what you will be using it for. Is it occasionally hanging pictures, or working full time as a carpenter? Larger and heavier tools can work with heavier materials, but can require more body strength and endurance to use. Smaller and lighter tools can be more precise, and used in tight spaces. So it can be useful to have several versions of a given type.

Cost is often a factor. You can get started with less expensive but adequate ones, and upgrade later. However very cheap tools may break or wear out quickly, and not be able to handle whatever you are working on. For personal production on a regular basis they should be hobbyist or professional grade rather than lowest grade. Used tools are typically less expensive, and often are perfectly fine for personal and small-scale production use. Finding used equipment in bulk, such as auctions, moving, and estate sales, may save money. Any duplicate or unneeded items found this way can be sold off or traded for ones you need.

Recognizing tool quality is a learned skill, as is knowing what grade you need for a given purpose. If you are unfamiliar you get get recommendations from more experienced people, books, articles, instructional videos, online reviews, and discussion forums.

Supplies, Parts, and Materials - To complete a project you need more than just equipment like tools and machines. Equipment is not generally used up in a single project. But some supplies, like sandpaper, wear out with use. Others, like paint, end up as part of the finished item. If you are merely tightening something that has come loose, or are assembling a packaged kit that comes with everything needed, you may not need any added parts and materials. But most projects will need materials like lumber and parts like screws that end up in the finished item.

There is such a wide variety of these items that we cannot list them all. Instead we try to note categories of common supplies, parts, and materials as part of the lists below. Instructional and reference sources have more specific information on what is needed. Published project plans will often include a detailed materials and parts list. When starting a custom project you can develop a list as you plan it. Then you can look at what you already have, and identify what else is needed to complete it.

Shopping for every small project takes time, and buying in quantity can be less expensive. So it can be helpful to keep some supplies, parts, and materials on hand. These can be leftovers from previous projects, packaged hardware assortments, or accumulated from second-hand sources. We will try to indicate what is helpful to stock as a starting point, but suggest getting other items as needed for particular projects.

There are many types and sizes of these items, so some way to keep them organized is useful. This can be Organizer Boxes with compartments and drawers, labeled empty jars and cans, or sometimes the box they came in. This author sorts them by name and size, but whatever method helps you find an item when you need it saves time and avoids buying duplicates.

In addition to purchased inventory, you can reuse items you already have but don't need, like old furniture, and items from your property like fallen or cut tree branches. Free and cheap outside sources can be found almost anywhere. Particularly good ones include scrap and wrecking yards, leftovers and removals from construction and renovation projects, and business trash. Always ask permission when scavenging from private property. You can also offer to clean up/remove/move items for people. For example, someone may have fallen tree branches which you can get free for the asking, or even get paid for removing them. Discarded or second-hand furniture can be used as work tables or storage, or as a source of lumber.

Making and Improving Your Own Items - A basic idea in these books is self-improvement. So if finances are more limited than time, or simply because you enjoy it, you can make or improve your own equipment. This lets you customize them to better fit your needs. For example, a workbench can be fit to your body size, what you are working on, and the available work space. A basic table saw consists of a motor, and an adjustable blade emerging from a cutting surface. But you can add different blades to suit the material, assorted guides for moving what you are cutting, and extension tables for managing larger pieces. To make or upgrade equipment requires already having some to work with, or access to other people's. However making everything from basic materials will take much longer than buying. So community members should consider what to make vs finding/buying already functional items.

Simple self-made woodworking projects include saw benches and saw horses, a stationary workbench, bench hook, miter box, and wooden mallets. A blacksmith can make many of their own tools, including a forge, chisels, hammers, punches, drifts, and fullers. A skilled one can make tongs, specialized hammers, hardies, flatters, and swages. Combining wood and iron work can produce cutting tools like axes and chisels, planes, drawknives, spokeshaves, claw hammers, and screwdrivers. David Gingery even wrote a book series on how to build metalworking machines from scrap. At a more advanced level, a well-equipped machine shop can make many of the parts for another machine shop.

Ready-Made Equipment - Places to find new tools include home improvement and hardware stores, online marketplaces, industrial suppliers, and direct from the manufacturers. Used tools can be found online on trading sites like eBbay or craigslist, or locally in the for-sale sections of social media. Pawn shops, flea markets, estate and garage sales are good sources for used tools. If you join a community of hobbyists or a Makerspace, you may find people who are upgrading or changed interests and are selling off/giving away items. You can sometimes borrow or rent tools, or use ones at community centers. A dedicated space for your own or group projects is less constrained by time and access, and has better control over tool selection and care.

Getting Experience - There are plenty of sources of information beyond what is in these books. Other books, both paper and digital, are a primary source. The Internet Archive has a vast collection of digitized books. Local libraries either have paper books, can borrow them from other libraries through inter-library loan, or have digital copies you can borrow. You can of course buy new and used books online and in bookstores. Hobbyist magazines and other publications are useful both for project information and specialty equipment sources.

A community of people doing personal production can teach each other whatever skills they already had or are learning. Formal classes are taught at community centers and trade schools. Informal ones can be found among hobbyist groups, stores that sell the relevant items, and at makerspaces where you can observe and try things. You can find local community projects, hobbyists, or professionals and offer to help or work for them, and learn while doing. Video tutorials and online forums on specific subjects have also become quite helpful in recent years.

3.0 - Basic Sets edit

Before working with any kinds of tools and equipment, you should learn how to use them and be protected from injury. To start with get some reference material and basic experience as noted in the previous two paragraphs. Also get some basic safety items like gloves and safety glasses:

Reference Material - At least one reference book on basic tool use to start with. Add additional books, videos, training classes, etc. as needed. There are many basic books available, but Tools and Their Uses, US Navy, 1992 is public domain and downloadable. The Internet Archive also has a number of basic books on home workshops and tools, which can be borrowed or downloaded.

Both paper and e-books can be used where you are working. To protect them from dirt and damage, a thick cardboard backing with rubber bands or spring clips, and a clear plastic bag or sheet as a cover is enough to start. E-books may need more protection for the display, like a wood tray with a hinged clear plastic lid.

Safety Equipment - Tools, and the materials being worked on, are usually stronger than body parts, and some injuries can't be healed. So a variety of safety equipment should be used to protect yourself. Loose clothes and hair can get caught up in moving parts, and should be changed or secured. We note some specific hazards in the lists below, and list general safety items here. Which of these are needed depends on what you are doing, and make sure you know how to use these through shop safety instruction:

- Eye Protection - such as Safety Glasses or Goggles.

- Hearing Protection - such as Ear Plug and Earmuffs

- Work Gloves - for hand protection. Types include cloth, leather, cut-resistant, fireproof, and rubber in varying thickness.

- Joint Protection - to protect body joints, such as Knee, Elbow and Shoulder Pads

- Respirators - to keep from breathing dust or harmful vapors.

- Welding Mask - to protect eyes from harmful UV light, and the head generally from sparks and heat.

- Work Clothing - can be both protective and useful. Thick materials like canvas and leather can protect from sharp or flying objects, or from heat. It can be in the form of clothing, or coverings like aprons or belts worn over other clothes. In addition they can have extra pockets, loops, and clips to keep often used items on hand.

- Fall Protection - These include hard hats (List 17), and reinforced shoes and boots to protect from falling objects, and safety belts to protect from falling off high places.

- Protective Covers and Shields - used around dangerous tool parts. They can either be built in as a tool feature, or added as an accessory. Examples are the blade cover on most circular saws, or the frame or cage around the operator of heavy construction equipment.

- Lockout Kit - When working with more than one person, these prevent turning on power or equipment while they are being worked on. It includes warning tags, locks, and plug covers.

Despite using safety equipment, injuries can still happen. So First-Aid Supplies should be available nearby. Most homes already have some. If a work space is some distance away or you are working away from home, a basic first aid kit should be located in the work space or your vehicle. Appropriate fire extinguishers and/or sprinklers should be available for any project with flammable materials. For outdoor work, water buckets and hoses should also be available to put out fires.

List 1 - General Home Use edit

These items are useful for common household tasks like hanging pictures, assembling furniture, or installing appliances. They are also needed for more advanced projects and maintaining other equipment. Most of them can fit in a medium-size portable toolbox or equivalent other container.

- Tool and Supply Containers

While household tools can be stored in a drawer or closet shelf, it is handy to keep them in a Toolbox of some kind. This avoids multiple trips when you need to use more than one, and keeps them all together. Almost any kind of container will work, as long as it will hold the majority of them (except the largest like hand saws), and is strong enough for the weight. Thick-wall cardboard boxes and plastic tubs are low-cost examples. Handles or hand openings make carrying them easier.

Manufactured or self-made toolboxes often have one more more drawers, removable/sliding trays, or smaller containers/dividers for small items (Figure 5.5-2). That makes it easier to organize and find what you need than a random pile. Additional types of tool carriers include large buckets, with optional tool organizers, non-rigid carrying bags and backpacks, and tool belts and aprons for when you want to keep some tools at hand.

Most tools are mostly or all metal, and power tools have motors, batteries, or cords. Many tools have accessories, like drill bits or various size sockets. So at some point a hand toolbox becomes too full or heavy. You can either have multiple smaller toolboxes, or use a larger one with wheels and a handle to make moving it easier. There are manufactured stackable sets with the bottom unit having the wheels and handle, or you can get a separate Hand Truck and strap multiple toolboxes to it.

Tools can damage each other, especially ones like files designed to cut metal. Smaller containers, especially ones with individual tool holders, within the tool box can protect them. Sharp blades can be covered with a cap or sheath, or wrapped in cloth. A tool roll of heavy cloth or soft leather can keep tools organized and separated from each other (Figure 5.5-3).

Besides tools, supplies, parts, and materials for projects also need storage. Small amounts can be kept in the same container as the tools, either loose in a compartment or in a smaller container to keep them from getting mixed with the tools. Larger amounts can be stored in a separate container or shelf, and whatever is needed for a given project pulled out as needed.

- Lighting and Inspection

You need to be able to see what you are working on. If permanent home lighting or daylight is not enough, there are portable options like plug-in lamps and work lights. Work lights can be mounted on stands or clamp onto an available surface. Battery options include flashlights, and headlamps which leave the hands free (Figure 5.5-4). Inspection mirrors are small adjustable ones on a handle to see in hard-to-reach places. Some have telescoping handles and built-in lights.

- Measuring and Marking Tools

These are used for marking where to make cuts or shapes, dimensions, or labeling parts for later assembly. Typically a cut line is marked, and then an X, squiggle, or shading is used to show the part being cut away. Cuts should be on the removal side of the line rather than directly on it. It is easier to remove material to get the final dimension than put it back once removed. So tool positioning should account for blade width.

- Pencils & Pens - Start with ordinary pencils. sharpener and eraser, and yellow and red marking crayons for dark and light raw wood respectively. Ink pen and colored marker lines are easier to see but harder to erase. The edge of Masking Tape can be used to mark locations and be written on, then more easily removed where appearance matters. Office sticky notes and other low-stick items can also be used for this.

- Scratch Awl - These make indented lines and points. They make a sharper line than writing tools and the indents help position a chisel or drill in the right place.

- Rulers - Flat steel rulers, preferably stainless to resist rust and heat. One to start with, 15-60cm (6-24 in) with fine-scale markings. Tape measures for longer distances. One roll-up steel type, 4-10 m (12-30 ft) for straight distances, and a cloth/plastic sewing type to measure around objects.

- Combination Square - For measuring and marking perpendicular or at an angle to an edge, and finding the center of an end. One 30cm (12 in) to start with.

- Levels and Plumbs - For finding horizontal and vertical lines. Spirit levels have liquid with an air bubble in a curved tube. Start with a torpedo Level (Figure 5.5-5), a small magnetized one suitable for general home use, like leveling appliances. A Plumb Bob is a light string with a substantial weight, usually pointed at the bottom. Gravity pulls it vertical. It can be used to transfer positions or align objects vertically. If attached to a marked frame or scale it can help align vertical, horizontal or sloped directions.

- Assembly Tools

For fastening parts together or take them apart again. Also for striking items to drive them together or apart or change their shape. These are mainly hand (unpowered) tools.

- Screwdrivers - Screws come in a variety of sizes with different heads, for which a matching driver should be used. Sets with common sizes are available. A basic set should have at least a large flat head, large Phillips, small flat head, small Phillips, and "stubby" (short shaft) flat head for small spaces. Since a lot of torque (twisting force) is often needed, they should be better than the cheapest grade.

- If an item doesn't already have screw holes, an Awl with a very narrow or pointed tip can make a small one. A sharpened small nail can also be driven then removed. Larger wood screws require drilling a hole the diameter of the solid shaft inside the threads to not split the wood.

- A small Cordless Screwdriver that accepts Hex Shank Bits can replace multiple screwdrivers and drill small holes. A set of screwdriver and small drill bits with matching shanks should be added if not included.

- Pliers - with flat jaws for firmly holding items using leverage. A Basic Set would include either a tongue-and-groove or slip joint type where the space between the jaws can be changed, a lineman’s with heavy-duty jaws, a needle-nose for reaching into small spaces, and a locking type which continues to hold without hand pressure.

- Socket Wrench Set - For larger screws and bolts that need more torque. A basic set includes a reversible ratcheting handle and different sizes of matching sockets to fit hexagonal-head fasteners. Small driver bits that fit one of the socket sizes can turn larger screws. Hex Keys (Allen wrenches) are used for hexagonal holes in a screw or bolt. A set of different sizes up to 1/4 inch (6 mm) to start with.

- Hammers - For striking with high force by combined arm and wrist motion. A basic set includes a Claw Hammer for driving and removing nails, a Ball-Peen for striking other metal tools or shaping metal, and a Rubber or Rawhide Mallet for when you don't want to damage what you are hitting. These can be anywhere from the 250-1500g (8-38oz) weight range depending on your strength and what you are hitting but a 500g/16oz claw type to start.

- Staple Gun - The manual version uses a hand-compressed spring to drive heavy staples. It can be used for fastening plastic sheet, fabric, and other thin material into soft wood and similar backings. Harder backings may require hammering the staples flush, or using sturdier fasteners like upholstery tacks.

- Cutting and Abrasive Tools

- Scissors/Shears - These have two sharpened blades on a pivot connected to handles. A toolbox version should have stronger blades and higher handle-to-blade length ratio to cut thicker material than household/craft scissors. A suitable heavy duty one is a Carpet Shears (Figure 5.5-6). The offset handles make it easier to cut on a flat surface.

- Utility Knives - Start with the kind called a "box cutter" with a retractable razor blade for cutting materials like cardboard. A straight edge can guide the blade along a desired line. If you use the knife often enough, it should come with or you can get replacement blades when they wear out. Blades are very low cost and not worth sharpening to a razor edge. An inexpensive Scraper/Spreader Set with different width and shape blades is useful for general cleaning, prying, and spreading. Thicker blades are better for scraping, while thinner flexible blades are better for spreading. A Razor Scraper holds a single-edged razor blade crosswise, and is used at a low angle on hard surfaces like glass.

- The Folding Pocket Knife has one or more blades which pivot into the handle. A Multi-tool includes other items besides edged blades. In all cases the movable blades make it safer and easier to carry when not being used. Traditional fixed-blade utility knives have their uses, especially outdoors or working with wood, but need a sheath when not being used for safety and to avoid damage to the edge. They should be single-edged so you can push on the back of the blade for extra force.

- Diagonal Pliers - have sharp rather than flat jaws. They are made of hardened steel and used to cut wires and similar long, narrow materials. They are usually built into lineman's pliers along with the gripping jaws. but adding a smaller one for tighter spaces or cut more closely to a surface is useful.

- Metal Snips function like scissors, but have much thicker blades and more leverage, often with compound action. This allows cutting sheet metal and similar hard materials. You only need the straight-cutting type to start, but left and right curve cutting versions can cut more complex shapes without multiple straight cuts.

- Hacksaws hold a narrow, fine tooth blade under tension in a frame. One standard 30 cm(12 inch) saw with a few blades of different tooth fineness to start. They are used to cut metal, plastic, and wood where a narrow cut or thin walls requires a thin blade with small teeth. Junior and mini saws use shorter blades and can be used in smaller spaces.

- Wood Hand Saws - These are for general cutting of wood to size. You can start with one short enough to fit in a toolbox with medium size teeth. Longer carpenter's saws can use the full stroke length of arm and body. They need a longer toolbox or are stored separately with something to protect the cutting teeth. The basic types are Crosscut with teeth to cut across the wood fibers (grain), and the Ripsaw with teeth to cut lengthwise along the fibers. There are many other types of Saws, but a smaller toolbox one and the two carpenter types for larger pieces of wood are enough for simple wood projects.

- Files and Rasps are used to remove small amounts of material by abrasion. Files have teeth the width of the tool, while rasps have smaller individual teeth. They are usually made of hardened high-carbon steel so they can cut other metals. They are fairly inexpensive, so start with a packaged set of six or more different sizes, shapes, and tooth fineness. This should include at least the bastard, double cut, round, and triangular types. Needle Files are very small ones with small teeth for confined spaces or fine work.

- File sets should have some handles, and a holder or wrap to keep them from damaging each other and other tools. A stiff toothbrush, detail brush or "file card" (a brush with fine metal wires) can be used to remove accumulated particles from the teeth.

- Sandpaper - is used to smooth surfaces, round sharp corners and similar finishing tasks. An assortment pack with different grain sizes is enough to get started. Grain is measured as particles per inch where fine grains have higher numbers, or direct size in microns. Sandpaper wears out and becomes clogged with particles, but is inexpensive to replace. A stiff brush can clean out excess particles. There are various types intended to be used wet or dry, with different types of grain and backing materials.

- The paper or other backing is flexible and can be cut from the back or folded and torn to whatever size is needed. Cutting from the grain side will damage blades. Sandpaper can be wrapped or taped to scrap wood or any other object to conform to the surface being sanded. Sanding Blocks are also made for this purpose. Fingernail files and hobby sanding sticks are useful for small spaces.

- Tool Care and Maintenance

Tools and work areas need some care, maintenance, repair, and cleaning. Care can be divided into avoidable problems and unavoidable wear. Water and high humidity causes steel and other metals to rust or corrode and wood to decay. Dry storage and work areas, and quickly removing water after use helps avoid these problems. A wiped on coating of oil, or storing in oiled paper or cloth, can help keep water away from metal. Wood finishes or chemically treated lumber can prevent rot. Paints and other durable coatings, and waterproof containers can protect both wood and metal items.

Sharpening - Using tools will eventually wear down sharp edges and moving parts. Casual use of a wood or metal saw may take years to wear down the cutting teeth, but if used regularly they require Sharpening or replacement. Hacksaw and razor blades are inexpensive and replaceable. More expensive cutting tools can be sharpened with files, sandpaper fastened to a flat surface like glass, Sharpening Stones, and Stropping with abrasive compounds. These are used in series with progressively finer teeth and grains until the necessary sharpness is reached. This varies by tool and its use. Start with a fine tooth file from those listed above and a two-sided sharpening stone with coarse/fine grain.

Repair - Other tool parts may need replacement if they become too worn or break. The assembly tools listed above are used to take tools apart, replace the part, and put them back together. Any kind of flat tray or small container can be used to hold loose parts while disassembled, so they don't get lost or forgotten. If there are many parts, a multi-compartment item like an egg carton, ice tray, or muffin pan can organize them in the order they were disassembled so it can be reversed during re-assembly. Magnetic Trays will both stick to any convenient metal surface and hold metal parts securely.

General Maintenance and Cleaning - These items don't need to be carried in a tool box, but brought out as needed. Many people already have some of these items, so add the rest as needed, or extra amounts for project work:

- Lubricants and Tapes - A saying is "WD-40 for anything that moves but doesn't and Duct Tape for anything that moves but shouldn't". Lubricants and tape have many uses, so some of each should be available. One can of penetrating spray lubricant, and a roll each of strong cloth (duct) and regular masking tapes to start. Other kinds of Lubricants and Tapes can be added as needed.

- Tools and machines with moving parts often need oiling at specific points and not others. Some oil containers come with a small nozzle, but a small brush or cotton swab can be used for hard to reach spots. Dedicated Oil Cans (oilers) that work by gravity or pressure are available for frequent or large-scale use.

- Brushes and Vacuums - Old toothbrushes and wire brushes can be used to clean up blade teeth, fastener threads and other small spaces. Soft hand brushes. a broom, dust pan, and trash cans are for collecting sawdust, metal shavings, etc. Hand and Shop Vacuums can clean up inaccessible or large areas. Some models are reversible and can blow air rather than suction when needed. Cotton swabs and small craft brushes can be used to clean or apply finishes to small areas.

- Cleaning Supplies - Old clothes or towels can be cut up, or cleaning rags purchased, for removing dirt, oil, grease, etc. Paper towels can be used but they wear out quickly. General household brushes, sponges, buckets and mops, water and household cleaners are used as needed to clean work areas. Cut-open plastic shopping or trash bags, and newspaper/advertising fliers can be used to protect surfaces, and table and floor coverings are available for larger areas.

- Ties - Twist Ties, String, Rope, and Bungee Cords have multiple uses for hanging, bundling, temporary clamping, and securing.

List 2 - Home Improvement/Do-It-Yourself Use edit

Adding the general-purpose items from this list to those from List 1 enables a range of more substantial home improvement and do-it-yourself projects. The combined items from both lists also serves as a foundation for more advanced and specialized projects. Additional items for such projects are in lists 3 to 22 below. As we said in Section 2.0, you don't need everything from any of these lists to start on projects. But the more items you have, the wider the range of projects you can do. The items in this list are grouped under headings, but you can start adding them in whatever order is needed for specific projects.

A wide range of materials, parts, and supplies are also needed for more advanced projects. There are too many kinds to include them all in these lists. We suggest starting with some packaged nail, screw, and bolt/nut/washer assortment sets with different size fasteners. This helps avoid making shopping trips for minor home projects. Other items can be accumulated as needed for current and future projects. All these items plus tools and equipment will need storage space when not being used, and a place to work when they are. This is covered in Section 4.0 below.

There are very many reference sources on Home Improvement and Do-It-Yourself projects. As a starting point, the Internet Archive's collection has over a thousand that can be borrowed for two weeks or downloaded, at no cost.

- Office & Media Equipment

If you are working from existing printed plans and instructions, you may not need much of these. But they can be used before and during a project to plan, design, research, and shop. They should be located away from active work areas or protected to avoid damage from tools, dirt, and dust.

Hand drawing has been substantially replaced by computers and software, especially for professionals, but drawing is much lower cost to get started. Even with computers, it is still useful for sketching ideas, or making notes and alterations to existing plans. Printed plans, however created, are still useful in the workshop, as they can be larger than screens, and if full size can be used directly as templates.

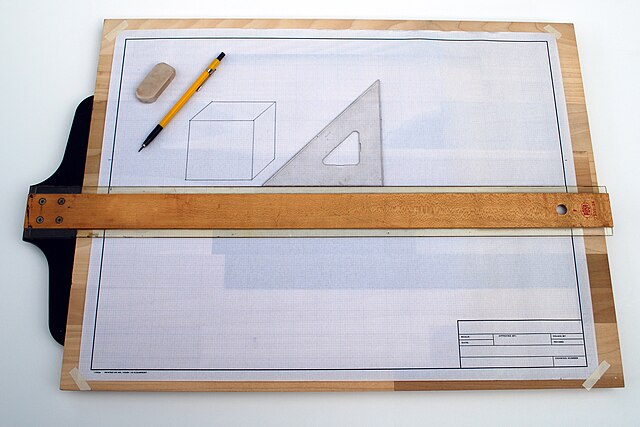

- Drawing Board - This is a surface to make drawings and plans of custom projects, customizing existing ones, or scaling templates to full size. An existing table or counter with a smooth top can be used to start, but any piece of smooth-surfaced rigid material can be used instead to avoid pen and tape marks. Portable boards (Figure 5.5-7) can be moved where needed and put away between uses. Narrow Drafting Tape or dots are used to hold drawing sheets in place, but can be removed without tearing or residue. Translucent Drafting Film (vellum) can be laid over other drawings and illustrations as guides. Graph Paper has a pre-printed grid, making scaled sketches easier.

- Drawing Tools are used to draw accurate lines and curves. A basic set includes a T-square, 45 and 60 degree triangles; engineer's scale, protractor, bow compass, one mechanical pencil 0.9-2mm lead diameter and spare leads, and an eraser. Added tools include mechanical pencils with other lead diameters, metric and architects scales, lettering, circle, and irregular curve templates, eraser shield, dusting brush; and dividers. A Drafting Machine allows lines at any accurate angle.

- Personal Computer and Peripherals - A computer system includes core hardware, a variable set of added peripherals, software, and optional data files. They can be used for multiple tasks like project research, communication, inventory, purchasing, project management, and design.

- A Computer Printer with scanning ability can be used to print out online or e-book plans for use in the workshop, and scan and enlarge printed drawings. Large plans and templates can be sent to a commercial print shop to make copies. A Webcam can provide live video conversations. A Smartphone can also do this and photography. Dedicated Digital Cameras have better lenses and controls for photography and video. A Video Projector can be used to transfer designs to physical items or templates.

- Computers and smartphones (which include a small computer inside) need software to function. Most come with an Operating System which controls the physical hardware and connected peripherals. Typically an operating system comes with basic Application Software or "Apps" for specific tasks beyond running the hardware. Examples are making simple text documents and drawings, or viewing websites on the Internet. There is a vast array of Additional Software which can be installed, depending on what tasks and projects you want to do.

- Work Surfaces and Clamps

- Portable - While some work can be done on the floor, supports bring the work to a comfortable height, and for longer items keep them from sagging or tilting while being worked on. Two Sawhorses, with optional boards and/or sheet goods laid on top are simple and flexible, and are a starting point if you have nothing else. They can be bought, but basic ones are easy to make and cheaper. Folding Portable Workbenches can have built-in vises, stops, and tool-holders. If they are very light they can move while working. Some have steps to use body weight to stabilize them. They can also be weighted with anything heavy to keep them steady.

- Clamps - Clamps in general are used to hold one or more items together or to the work surface to keep them from moving. They can be much stronger than muscles and leave the hands free for working. A single clamp can allow items to rotate, so at least two medium-size ones are needed to start with. Additional clamps of various types and sizes are desirable (Figure 5.5-8). There are specialized clamps that use Straps or for Holding Corners that can be added later as needed, and temporary ones can be made from rope and sticks, with wedges driven under the rope to apply pressure.

- Workbenches - These are either stationary, or if wheeled generally stay within a workshop area. Their weight and rigidity keeps items from moving or vibrating from tool forces. They typically have built-in Vises and clamps, or are designed so temporary ones can fix the work to the bench. Vises generally have larger faces to apply pressure and are stationary, while clamps are typically movable. The intermediate clamp vise can be temporarily clamped where needed. The Bench (Figure 5.5-18) and Woodworking Vices are the most common types. The latter have wood vise faces to avoid damage to items.

- There are a number of specialized tools and accessories to hold items to workbenches. Some have Bench Dogs or Pegs or Holdfasts that can be inserted into holes to position or secure items. Shaped inserts can better hold round or other items that don't match the jaw shape. For some projects, custom holding jigs need to be self-made. For any kind of vise or clamp, softer materials like wood, leather, or rubber can be inserted between the jaws to prevent damage to the work.

- Many workbenches have storage shelves, hooks, or drawers below the bench top. Wall-mounted benches often have additional shelves or cabinets above the bench for storage. Free-standing benches (not against a wall) allow access from all sides and working on overhanging items. If large items will be worked on, temporary supports or other shop tables can be used to support the excess. Depending on use, bench top height can be for working standing up or sitting, or a taller chair or stool used to sit at a standing bench. Some benches have built-in electrical outlets for power tools. Otherwise corded tools or battery chargers can be plugged in elsewhere.

- Reach and Positioning

Some projects involve reaching/working beyond arm reach, either above standing height, below a floor, or long horizontal distances. Using arms overhead for extended times is also tiring. Two basic approaches to this are tool extensions to increase reach, or ones to position the body closer to the work.

- Extension Handles and Poles - Some tools are designed to accept screw, pin, or bolted extensions to their handles, and some handles can change length by Telescoping. Other tools have a grabbing claw or hook built into the end. Improvised extensions can be made by inserting a tool handle into light hollow pipe or tubing and securing by screws. Another method is side-to-side securing of handle to any pole using devices like tape, Hose Clamps, U-Bolts, wrapped wire, or Cable Tie. This is generally less secure.

- Stepladders have steps or rungs to climb and stand on. They come in a wide variety of sizes, and are either free-standing or leaned against something. A two-step version may be enough to reach ceiling lights and high shelves indoors, but a 2 meter (6 foot) one with four legs is more stable and provides places to set or hang tools and materials while working. Some versions have a small fold-out shelf for this purpose. This size is sufficient to start with. For outdoor use extension or folding ladders can be adjusted to the task at hand. If you expect to reach a roof or tree limb, the length can be chosen based on that height.

- Modern ladders are rated for weight. Select one rated for at least your body weight plus the heaviest item you expect to lift up it. A falling ladder or falling off one can cause serious injury. Move the ladder rather than leaning or lifting heavy items beyond the legs. If the ground is not level or firm use boards or blocks to fix that. Secure the ladder if needed to what you are climbing up, or braced to the ground with diagonal poles or staked ropes. Secure yourself to the ladder or what you are climbing with hooks and ropes/straps/safety belt to prevent falls.

- Work Platforms provide more horizontal surface to stand on or place things than ladders. They are useful when horizontal movement is needed while working. One or two sturdy boards placed across two ladders, or one ladder and building steps are simple versions. Since loose boards can shift, they should be clamped or have angles or blocks attached to prevent sliding off.

- Moving and Lifting

Moving heavy objects or large amounts of supplies happens often on larger projects. Moving or lifting items over 20 kg (40 lb) or carrying multiple smaller or lighter items is difficult by hand, and benefits from various transport and lift devices. Some bags and boxes saved from previous shopping or discarded by stores may be enough to start with. Horizontal movement benefits greatly from wheels. Depending on the task, a Hand Truck, Flatbed Trolley (moving dolly) or Wheelbarrow can be used. Tubs, Buckets and assorted small containers are useful for storing and moving items like fasteners, bulk materials, liquids, and groups of tools. Workshop machines and carts can come with wheels or have them added. This allows moving them out of the way when not being used, or to where needed while working.

For moving large amounts of material or larger single items, motorized vehicles of many types and sizes exist. The most common are passenger cars, pickup trucks, and enclosed vans. Trailers can be attached to many of these vehicles. Flat or open bed loads can be protected and secured by tarps, nets, elastic or chain hooks, and ratcheted straps. Blocks, wedges, and bars can prevent loads from shifting. Securing loads is important for balancing trailers whose deck extends beyond the wheel base. Shipping containers can carry large amounts of goods and serve as temporary storage or even a small workshop.

Pulleys are used for lifting, dragging, or changing the direction of a force. A single rope and body weight is enough for smaller loads. Sets of pulleys can be combined for added leverage. Inclined boards set on a step or block and fabricated ramps can help withe height changes. The ledge at the bottom of a hand truck and many other objects can be used as Levers to lift objects enough to place supports under them or get them onto wheels. Back Supports may help avoid injury when lifting heavy items with body strength, but proper technique is more important.

Winches multiply leverage with cranks and gears. There are both hand and powered versions. Temporary hoists can use 1-3 poles with anchor ropes as needed. They can support pulleys, hooks and other lifting gear high enough for a given task. These are the Gin Pole, Shear Legs, and Tripod. Commercial lifts and cranes can be rented for occasional use, or are supplied while delivering large loads.

Jacks - are devices to lift heavy weights or apply bending forces, generally more than simple levers. There are may types using ratchets, screws, air pressure, or hydraulics. The type included with most passenger cars for changing tires is enough to start, but a bottle jack of 10-20 tons capacity is a useful addition. Always make sure the jack is firmly supported. On bare ground it is likely to push itself into the ground rather than lifting a heavy object. Boards, timbers, or concrete blocks can spread the load. Also place timbers or other supports as the item is lifted, in case the jack slips or the load shifts sideways.

- Measuring and Marking

- Size Measures - The ruler-type Caliper has a sliding jaw attached to a ruler, with a vernier scale for accuracy. The inside and outside spring types can take and transfer measurements. These three 6-12" (15-30cm) in size to start with. Dial and digital calipers can make more accurate measurements, but not as accurate as a micrometer.

- Weight and Volume Measures - For measuring bulk items and liquids. These can be conventional kitchen and bathroom scales, measuring spoons and measuring cups. Empty clear/translucent containers can be filled with measured volumes of water and marked for shop use. This is useful for materials that will stain or are toxic that you don't want to contaminate your measuring set.

- Note: Some of the angle, curve, and spline tools that follow overlap the drawing tools in the office section above. If you already have those, you may not need more to start with. Larger versions are useful for measuring and marking larger physical projects as opposed to scale drawings. The need for them depends on what projects you are doing.

- Angle Measures - There are various devices for setting right angles (90 degrees or perpendicular). The Try Square is 20-50 cm (8-20 inches) is for smaller accurate work. The Steel Square is a larger one-piece device with engraved scales. Angled and sloped cuts are either described by the two scales, like "6:12", or calculated from the angle tangent. For cutting sheet goods there are squares the full width of a standard sheet. Sheet goods are generally manufactured with right angles, so an alternate method is measuring the lengths on opposite sides from the corners, and connecting them with a straight edge.

- The Speed Square is a triangular Set Square with a built in fence. This can be pressed against a board edge to mark a cut, or clamped to it to guide a circular saw. A Protractor has an angle scale, and the bevel type has a pivoting arm to mark angles. A Sliding T Bevel can set and transfer angles when you want them to match. One try or steel square is enough to get started, depending on the size of the projects.

- Curve Marking - A Compass has two sharp points, or one point and pencil/pen for marking arcs and circles. The distance between the points is set against a ruler to the radius desired. The regular and beam/trammel types will mark small and large radii and are enough to start with. Very large curves can be set by hooking the end of a tape measure to a small nail at the center point, and securing the sharp point, pencil, or pen to the tape with a small Binder Clip

- Reduction Compass - consists of two double-pointed arms on a fixed or sliding pivot. The ratio of point distances is maintained allowing scaling up or down, such as from a drawing to a full-size item.

- Flat Splines and French Curves can be used for non-circular curves. Lines on curved surfaces like cylinders can be set by marking two or more measured points, then wrapping folded paper or other bendable but not stretchy material between them to mark a line.

- Carpenter's Level - 60-120 cm (2-4 foot) (Figure 5.5-9). A longer version of the torpedo level from list 1. This can span more distance and be more accurate, but is harder to use in small spaces. For longer distances a level can be set on or against a straight piece of finished lumber with parallel sides or any similar object. Once a horizontal or vertical line is determined, slopes can be set by measuring perpendicular to one end.

- Additional Hand Tools

- Screw- and Nut Drivers - The basic screwdriver set can be extended to cover most projects with about 30 pieces from a large standard plus precision screwdriver sets. Magnetic tips are useful for any driver. Nut Drivers have axial shafts like screwdrivers, but with tips that fit different size nuts and bolt heads. Their use overlaps socket wrenches with extension bars but can be used in smaller spaces.

- Hand Saws - Compass and Keyhole Saws have narrow blades for making curved cuts. They differ in size and tooth fineness. Interior cuts can be extended from a small starter hole made with a drill or chisel. A Coping Saw has a very narrow blade with small teeth, and a frame to keep it straight under tension. The small teeth are good for thin material. The Bow or Frame Saw is a larger version. Interior cuts can be made by unhooking the blade, putting it through a starter hole, and re-attaching it. The blade can be rotated as needed for the cutting direction. A Bench Hook is a simple accessory, usually self-made, to keep an item steady and slightly raised while cutting, so you don't damage a work table. Hook a pair of them over the edge of the table and press what you are cutting against the upper blocks.

- Hand Backsaws have a reinforcing strip to keep the blade straight and can be used with a Miter Box to guide it. They are used for cutting to length and accurate crosscut angles. They come in various sizes and tooth fineness from the larger miter saw, to tenon, dovetail, and razor types. Ones with offset handles are used to cut pegs and other protrusions flush. Hand saws require periodic sharpening with use. Specialty clamps, file jigs (to even tooth height), and Saw Sets (to set kerf width) are available, but can be made/use other tools. The actual sharpening uses files and sharpening stones.

- Hammers - Add other sizes of hammers with metal heads as needed, either smaller and lighter for fine work, or heavier up to the two-handed Sledgehammer. One or more hardwood mallets or Dead Blow Hammer for when you don't want to damage what you are striking, with less rebound than the rubber mallet. These often have soft striking faces with sand or metal shot filling the head, which absorbs the rebound forces. The light Tack Hammer has one magnetized head to start small tacks and nails, such as for upholstery. The un-magnetized head then finishes driving them in. Pliers can be used to keep fingers out of the way when hammering small fasteners and other tools.

- Hooks and Picks - These are small tools similar to dental Probes and Explorers, mainly used for reach in small spaces and holes. Start with a basic set with several shapes.

- Hand Rollers - apply pressure, smooth, or spread material across surfaces. There are various types for multiple uses like flattening roofing, carpet, and wallpaper, or spreading adhesives. Start with a small rubber roller about 4 in (10 cm).

- Holding and Grabbing Tools - These use inside or outside grips, claws, or magnets, to hold or retrieve parts in difficult locations, or where they may fall and become inaccessible. Often used when threaded parts are near the end of the thread to start or remove them.

- Shop Magnets - The extension and sweep types are for retrieving dropped items and metal cuttings. A strong shop magnet can be used to locate nails and screws in a wall by feel, and so also find metal framing. A Stud Finder is a more advanced device for finding wall posts (studs).

- Deburring Tools - For removing rough edges left by cutting tools. Files can also do this task, but a specialty tool set is sometimes more efficient on softer materials and longer edges.

- Pry and Demolition Bars - These use leverage to remove nails, pry items apart, or start to lift heavy items. They can use hands or hammers to insert. They come in various sizes and shapes like the Cat's Paw, Crowbar, and flat pry bars. Claw hammers have a built-in prying tool, but additional ones are useful.

- Chisels and Punches - Cold Chisels are used to indent or cut thinner metal, and score, chip, or split masonry. Punches are used to indent or pierce leather, wood, or metal. Hollow punches can make well-defined holes in thicker material. Matching Die Blocks support the other side so the surrounding area is not bent (Figure 5.5-10).

- A Center Punch is used to mark where a drill will cut and keep it from wandering. A Nailset is a punch with a small head, for driving a nail flush or slightly below without damaging the surrounding material. Drift Pins are either straight or tapered. They are used to either transfer hammer impacts to hard-to-reach places or align holes before assembly. Start with a punch and chisel set of assorted types and sizes plus one medium Wood Chisel for minor trimming and cutting of wood and other softer materials.

- Wrenches - Add to the basic socket set a larger set with multiple handle sizes and a larger range of sockets. Sizes up to 1 1/2" SAE and 38mm metric will cover all but the largest projects. Using two handles with a nut and bolt allows more tightening force. The most common sockets have 6 sides, but 8 and 12-sided ones are available for specific bolts and nuts. A Torque Wrench allows a specific tightening force when this is important.

- Open or close-ended single piece Wrenches can apply higher forces that would damage a ratchet type handle. Their drawback is having to remove and reposition for each turn in tight spaces. A combination wrench has one open and one closed end. Using the ratchet handle first, then this type for final tightening minimizes the work.

- Adjustable Wrenches have a wheel to change the jaw opening. Four sizes from 6-12" (15-30cm) should cover most needs Pipe Wrenches have serrated rather than flat jaws to better grip large nuts and heavy pipe. These come in a wide range of sizes. One medium size to start. Strap Wrenches use a strap or chain to grip rather than jaws. A Ball-End Hex Key can be used at an angle to the screw in hard to reach places. Sizes from 0.05-0.5" and 1.27-10mm in addition to the plain hex keys should cover most needs.

- Pliers - As needed, add Pincers and Nippers, to grab or cut across the handle rather than along it. They are useful for pulling items like nails, or cutting protruding items flush. Add to a the single locking pliers a set with other sizes and jaw shapes. Add other sizes and lengths of other pliers from List 1 as needed.

- Specialty pliers include ones to install and remove Retaining Rings. The rings have different styles and sizes, so you may need a set, or one with replaceable tips. Needle-nose pliers can open small chain links from the inside, but Fixture Chain Pliers open rather than close when squeezed and can open larger links. For even larger chain, insert the head of a compound leverage tool like metal snips or bolt cutter and pull the handles apart.

- Bolt Cutter - For cutting thicker rods or bars than pliers using compound leverage. For even thicker items use a metal hacksaw, angle grinder, or reciprocating saw.

- Portable Power Tools

There are many types and sizes of Power Tools. The portable ones are meant to be moved to the work and used with one or two hands, while stationary ones are larger and have the work brought to them. Most use electric power either from a battery or cord. Batteries allow moving anywhere without worrying about cord length and handling, but they eventually need recharging. Battery packs and chargers add to the cost. Corded tools generally allow higher power levels and longer running time. Which to use depends on the projects you are doing.

Most power tools come in a range of quality and power level. The standard unit of power is the Watt, or kiloWatt (kW or 1000 Watts) for larger amounts. Watts are Amperes (A or Amps) times Voltage (V) at the power source, usually a wall outlet. Power tools are often labeled in Amps of maximum current draw. We assume 120 V source in our discussion, and 240 V for high power devices, but voltages vary by country. Some larger motors for stationary tools are rated in Horsepower of 746 Watts each.

Caution: Regardless of how power is described, take care to not go over 80% of the rated capacity of any electric circuit, either permanent wall sockets or extension cords. Motors that are starting up or stalled can draw more than their rated power, and overloaded wires can heat up, which is unsafe. Long cords have reduced capacity from resistance losses. Their limits are either supplied with the cord, or can be found from reference tables.

- Extension Cords allow working farther from a power outlet. Cords should be rated for the highest power tool you expect to use, and for outdoor use if you expect to use them that way. If you are moving around or climbing up, tie an Overhand Knot with the ends of the tool and extension cords before plugging together. This prevents them from pulling apart. To use multiple tools and work lights without constant plug changes, you can use cords with multiple socket ends, separate multi-way adapters, or Power Strips.

- Electric Drill - Start with one corded drill around 6 Amp (720 W) power and a set of standard wood drill Drill Bits up to the drill chuck capacity. If you expect to work with metal, there are bits made of stronger materials with a different cutting angle. A Drill Gauge can help identify the size of a bit if it is not clearly marked or worn off.

- The Hammer type drill can apply forward impacts to better go through hard materials. Many drills have side handles for better control, and a depth gauge to know when the hole is deep enough. Specialty Right Angle Drills have the chuck mounted sideways to the grip rather than axially, which allows drilling in smaller spaces. Hand Drills of various kinds still exist but are mostly obsolete. They are used where power is not available or to save weight and space in a toolbox.

- Drill Accessories - There are many other accessories that can fit in a drill chuck. Driver Bits can be used in place of screwdrivers and socket wrenches. They are faster but with less control. A driver assortment set is enough to start. Wheels include sanding, wire, and buffing types. Specialty Drill Bits include countersink, counterbore/spade, expansion, and auger types for wood, and abrasive stones for metal.

- For large holes a stationary drill press (List 8) handles the higher torque better. Alternately use a smaller starter hole, then a hand or power jigsaw, or a Hole Saw to enlarge it. Mixing Paddles can be used for paint and grout, but for large or stiff mixes, dedicated mixers should be used with more torque. Various kinds of Hand-Powered Drills still exist, but are mostly used where power is not available, to start a hole, for small spaces, or countersinking.

- Circular Saw - uses a high speed blade to make straight cuts. Start with a portable corded type, with a 7.25 inch (18.5 cm) wood cutting blade with carbide teeth. Blades with different tooth sizes and for other materials are available. Smaller and larger saws are available, as are cordless (battery powered) ones. The latter typically use smaller blades due to battery limits. Due to high cutting forces, whatever is being cut should be secured to prevent movement, and use a firm grip on the tool with both hands. For accurate cuts, a straight object is clamped to the work, offset by the blade distance from the base plate edge.

- Reciprocating Saw - moves the blade forward and back rather than rotating. Longer blades allow cutting thicker items than a circular saw. Since only the blade is in the cutting area, they can work in tighter spaces than a circular saw. A variety of blades are available for different materials, and in different lengths and stiffness. Start with a pack of assorted blades. This tool is generally less accurate than a circular saw, but clamping something to the work to guide the tool can improve accuracy.

- Jigsaw - This is a type of reciprocating saw where the blade goes vertically through a base plate. They are most useful making straight or curved cuts in boards or sheet goods. A wide assortment of blades are available, so start with a pack for different materials.

- Angle Grinder and Rotary Tool - These use high speed wheels and bits for tasks like cutting, grinding, and sanding. They differ in the direction of rotation and size. Angle grinders rotate at a right angle to the tool body, and are generally larger and more powerful. Rotary tools, such as the Dremel brand, rotate in line with the body, similar to electric drills. Compared to electric drills they spin at much higher speeds but with lower torque at the same power. Start with one of either type depending on the size of the work.

- Heat Gun - produces much higher temperatures than a hair dryer, and should never be used for that purpose. A hair dryer can be used for milder heating. Heat gun uses include paint stripping, shrink wrapping, softening plastic for bending, and general heating and melting. Higher temperatures require an oven or furnace, but heat guns are portable and can cover larger areas.

- Stationary Equipment

Stationary tools and machines are intended to be fastened in place when used, or are heavy enough to stay in place on their own. In general they can be manually operated or powered, but the ones here are all powered:

- Power Miter Saw - These perform the same function as a hand backsaw and miter box but are much faster using a powered circular saw blade. Basic versions have a horizontal angle gauge and fence. More advanced ones have blade tilt and slide features, clamps for the material, and projected lines for the cut. A workbench, sawhorses, or rollers support longer and heavier lumber, keeping it straight and balanced while cutting. These saws generally have mounting holes to secure them to a board or table, and some come with portable or wheeled stands.

- Bench Grinder - This mounts high speed abrasive, wire, or buffing wheels to sharpen, remove material, clean, and polish. Care should be taken that the wheels are balanced and secured without wobble. Grinders throw cuttings at high speed and can generate sparks, so gloves and face protection or a safety shield should be used. On metal the heat generated can affect the Temper and burn hands, so dipping in water periodically can cool the item.

- Wet Grinders turn more slowly and apply water to the wheel to avoid overheating. They are typically used for blade sharpening. A Sharpening Jig holds the tool at the right angle to the abrasive. Start with a 6-8 inch (15-20 cm) bench grinder with abrasive wheels. Bench grinders can be fastened to a workbench, or to a stand if larger items need to be worked on.

- Air Compressor - This is useful for inflating tires and other items, and also for air tools like nail guns and paint sprayers. Start with a small one light enough to move where needed plus an air hose and attachments kit.

- Care and Maintenance

Building Maintenance - Homes and other structures require maintenance to stay functional. Many of the tools and equipment listed above can also be used for repair and replacement, but the following are mainly used to diagnose and fix problems:

- Test Lights - are used to check if an electrical outlet or other device has a voltage (power). They are used for safety, to make sure power is off before doing work, and to see if a device is not working from lack of power, or has an internal problem.

- Rubber Plunger and Snake - are used for clearing common blockages in household pipes.

Vehicle Maintenance - After their homes, the next most important items for many people are their vehicles. This includes passenger cars, light trucks, motorcycles, bi- and tricycles (manual and electric), utility trailers, golf carts, riding mowers, and all-terrain vehicles. Some of the tools above, such as socket wrenches, can also be used for vehicle maintenance. There are many vehicle-related specialty tools and supplies, but the following basic items are commonly used at home:

- Fuel Containers - (see List 12)

- Tire gauge

- Accessory Tire Inflater - A small compressor, often using a 12 Volt car accessory socket. It is mainly intended for vehicle and trailer tires, but can also be used for wheelbarrow, mower, and other small tires.

- Battery Charger

- Engine Oil, Grease Gun and other lubricants

- Engine Coolant

- Vehicle Cleaning Supplies

General Maintenance - When damaged, stripped, or frozen fasteners need to be removed, there are several ways to deal with it. Dirt and rust can be removed with brushes and rags, or specialty rust remover fluids. Penetrating spray lubricants and strong wrenches may then be enough to remove them. Many kinds of Extractors are made for removing broken or frozen screws, nuts, and bolts. If the hole is too damaged to reuse, it can be re-threaded with taps and dies, an insert or filler material used to patch it, or a new hole drilled nearby.

4.0 - Upgrading and Specialization edit

This section covers upgrades to storage and work spaces. It also introduces the more specialized expansion set lists in Sections 5.0-8.0. They build upon and add to the items from lists 1 and 2 above. Each list covers a category of projects, but some projects will need items from two or more of them. Some kinds of upgraded space can be used for many types of projects. Other projects need specialized areas better suited to their needs. We note such cases under their respective lists.

Tools, larger machines, parts, materials, and supplies will accumulate as you move from basic to more advanced projects. So more room to store and use them is needed. Section 3.0 mentioned basic items like portable toolboxes and storage containers. Temporary outdoor space can use sawhorses and boards or mobile/folding workbenches. Moving vehicles out of a garage can provide temporary indoor space. Eventually more permanent workshop space becomes preferred over setting up and taking down temporary ones. It saves time and allows better working conditions and task flow.

Storage edit

Storage Areas - When starting out, tools and supplies can fit in small household or vehicle spaces using items like a portable toolbox, drawer, and plastic or cardboard storage boxes. Over time you can outgrow such small storage, it gets harder to keep things organized, and it takes longer to find items and put them back each time you want to work. So custom storage becomes useful. This can be in a garage, spare or utility room, outbuilding, or other space. Since floor space is usually limited, multi-level units like Storage Shelves and Cabinets are very useful.

Tools, parts, materials, and other supplies can be quite heavy, so storage units should be strong enough for their loaded weight. Shelves and cabinets can be wall-mounted or freestanding, fixed or movable, and any size required. They can be integrated with machines and work surfaces if desired. Longer or larger items can rest directly on the floor, on support blocks and pallets, leaned against or hung from a wall, stored on racks, or use taller cans and boxes to keep them vertical. Tools and equipment with wheels can be stored out of the way, then pulled out as needed.

Storage Containers - help keep items organized and accessible, but out of the way when not being used. Some portable tool boxes have drawers, as do the larger wheeled or stationary tool chests and storage systems. Organizer boxes, empty jars and cans, or open bins can be used for bulk items like nails and screws. Cardboard boxes are often free from stores if you ask, and come in all sizes. Sturdy ones are preferred. Labels help finding the right items once many have accumulated. A pack of blank address labels and a bold marker can serve for this.

Workshops edit

When you add dedicated working space to storage, it becomes a Workshop (Figure 5.5-11). Workshops can be specific to one type of activity, or more general supporting multiple types.

Types - Stationary workshops come in all sizes from a craft area in the corner of a room, to garage and basement space, to freestanding buildings that can be as large as needed. Mobile storage and workshop spaces are useful for working in different locations. This can be as simple as a toolbox in an unmodified vehicle, an enclosed trailer or modified truck for tools and materials, or as large and complex as multiple shipping containers holding equipment and inventory, and temporary structures to set up on arrival.

Some homes may already have space for a workshop, or one in place. But other homes and many apartments don't have enough space or weight capacity for the kinds of projects you want to do, especially if you go beyond basic home improvement/do-it-yourself ones. You can try to find existing shared workshop space in the community, move to a home that has one, or lease/buy a place for a new private or shared workshop space.

Setup - The items in these starter and expansion sets enable making and building things. That includes building some or all of a workshop. Shelves, work tables, chairs, and cabinets within a workshop are collectively called Shop Furniture. They can be built similarly to household furniture. Simple workshops can be built with the basic items from Section 3. Larger and more complex workshops may need woodworking (List 8) and construction items (Section 8.0) to complete. When to build a new workshop depends on what you already have available, the need for added space, and outside factors like cost, financing, and permits.

Setting up work and storage space, furnishing it, and getting all the tools and other items to work with can be a very big project. So typically it is divided into smaller stages. The completed part can then be used to help finish the rest. For example, once you build a workbench, you can then use it to help build the other shop furniture.

Workshop Buildings - are one or more suitable existing or purpose-built structures on a property. A given property may be residential, commercial, industrial, or bare land. Workshops can be additions to an existing building, or detached free-standing structures. On commercial or industrial property they may only take up part of a larger building.

The building's size, location, and features depend on what kind of projects are intended. When planning them, you should consider future growth in addition to current needs. This can be handled by over-sizing a structure, planning for additions and extensions to it, or adding additional separate structures. There are a number of reasons for a separate residential workshop. They include (1) outgrowing existing home space, (2) excessive noise, dust, debris, and fumes, (3) extra power and light requirements, and (4) better access for vehicles and moving large items.

Planning - Workshops should be planned and designed for their final form. This minimizes later changes and rework. They don't have to, and seldom are, built and outfitted all at once. When planning them, the following items should be taken into account:

- Size - How much workshop space is needed is determined by the size of the projects being made, and the shop furniture, assembly areas, tools, stationary machines, parts, materials and supplies being stored and used. Workshops can be used by one person or many, so there should be enough space to not interfere with each other. Enough additional space is needed to move around and for large items to overhang and move through machines. For some projects, outdoor space can be used temporarily to extend the working area.

- Access and Load Capacity - Vehicle driveways, foot paths, ramps, and regular and large doors are needed for access. Access features, and the workshop floor, walls, and upper areas for hanging items, must all be able to support the total weight of everything moved or stored on them, which can be quite large. For heavy machinery and storage, thicker concrete slabs or deep footings may be needed. If there are upper floors, the heavier items should be on the lower floors. Stairs and lifting devices can ease moving items between floors.

- Storage and Growth - Shops should not be overcrowded and items piled haphazardly. That is both unsafe and hard to use. Plan for enough space to properly store current tools, equipment, materials, parts, and supplies, and room for future growth.

- Lighting and Power - Workshops need adequate lighting, either natural or artificial. Natural light includes windows and skylights. Artificial light includes fixed ceiling units, plus task and portable lights where needed. Enough electric power is needed for lighting, heating and cooling if not already provided, and for running all the power equipment being used. This may require upgrades to existing systems. Power is preferably routed through ceiling drops and wall channels for flexibility, and to avoid trip hazards from cords. Electrical conduit is used to protect exposed wiring from damage.

- Water and Environment - Access to water, such as a utility sink or outdoor spigot is desirable. So is ventilation if fumes or dust are generated. Temperature and humidity should be controlled enough to prevent rust, wood rot, and be comfortable to work in. Access doors should be large enough to move materials and finished items through. Some storage and work areas can be outdoors, with partial protection from rain and wind. For example, vehicles and mobile equipment can be stored outdoors, but they will be better protected with at least a roof over them.

- Layout - The contents of a workshop can be arranged into general areas used for multiple activities, and those specific to a particular task. The layout should consider your workflow. In general, work starts with delivery and storage of supplies, materials, and parts. Materials are then converted to finished parts, finishes applied, and assembled into completed items. Unless the completed items are to be used in the shop, the last step is delivery. A "U" shaped layout often works for medium size shops, with supplies and finished items both going through a single large door, and steps in-between progressing around the perimeter.

- Safety - A first aid kit or station should be available if a workshop or vehicle is away from a home that already has one. Manual and low-power tools may not need them, but sprinklers and fire extinguishers should be considered for fire protection. Smoke detectors and Fire Blankets may also be useful. Fireproof or outside storage may be needed for flammable materials.